Carton Packer and Wrapper

Discover how the Packer and Wrapper can enhance your production

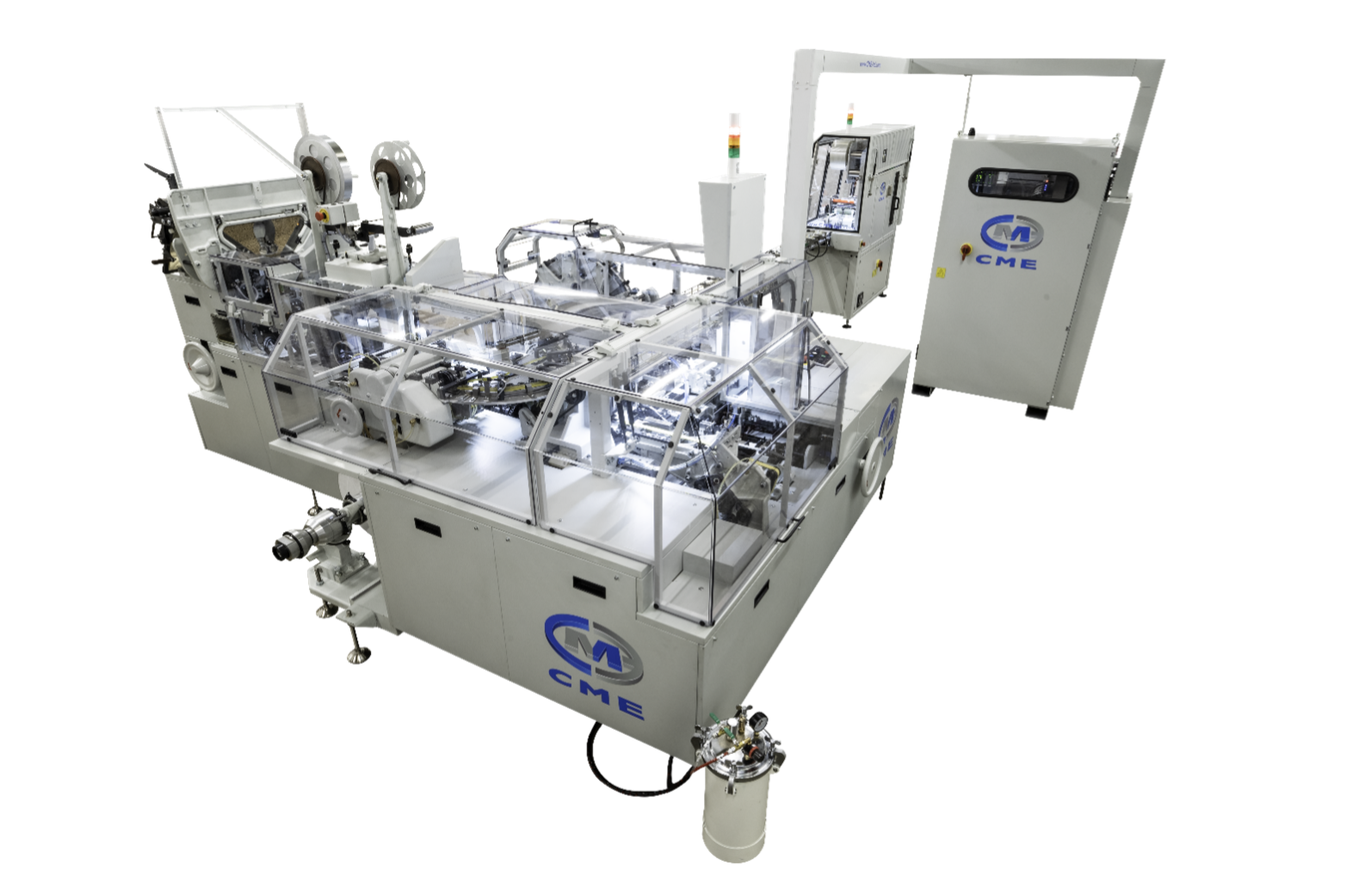

Cylindrical Preroll Hinged Lid Cartoner and Packer & HLP Cellophane Wrapper

Boost your packaging efficiency with the Hinge Lid Packer

View All Key Features

Watch the HLP Combined Cartoner, Packer and Wrapper in action!

A winning combination for accelerating your cylindrical pre-roll packaging production!

Watch this overview of the Cylindrical Preroll Hinged Carton Packer and Wrapper.

HLP Hinged Lid Cartoner and Packer

The machine will run at an operating speed of up to 120 ppm depending on THC product quality and cleaning regime. Initial operating speed TBA. (Bag filler 60ppm). The blank layout of the pack is to be confirmed prior to order placement.

View All Key Features

Key Features

The HLP Hinged Lid Cartoner and Packer can package large quantities of pre-rolls in a cigarette format.

The Machine will incorporate:

- Single track filler bed

- Conventional turret hopper

- Ends detectors

- Twin reel foil delivery, core size to be confirmed

- Steel on steel embossing

- Rotary foil serration and cut-off

- Predisposed for fitment of CME rotary coupon unit

- Plough folded lid flap

- Sealer bed plough folding

- Mechanical front flap folding

- 48 stage drying drum

- Centralised lubrication system

- CSA Standards

Cellophane Wrapper

To supply 1-off Cellophane Wrapper, to operate at speeds up to 120 ppm depending on THC product quality and cleaning regime. Initial operating speed TBA. (Bag filler 60ppm). The machine will be set up to wrap packs with polypropylene film size to be advised.

View All Key Features

Key Features

The Cellophane Wrapper can wrap large quantities of pre-roll packs with polypropylene film.

Technical Specs:

- Right hand infeed (left hand infeed available upon request)

- Standard infeed conveyor and hand feed chute

- Powered Unwind Unit for Jumbo tear tape

- Set for 1.6mm self-adhesive tear tape (alternative options available on request)

- Single reel film delivery (alternative options available on request)

- Manual splice (alternative options available on request)

- Static eliminator

- Twin film alignment sensing

- Mechanically driven rotary film cut-off (servo driven print registration available on request)

- Carbide Knives

- Reciprocating and retractable end seal heaters, coated heater surfaces

- Reciprocating and retractable top heater (Wrap tidying kit)

- Static bottom heater (Wrap tidying kit)

- Packet eject (automatic with manual override)

- CSA Standards